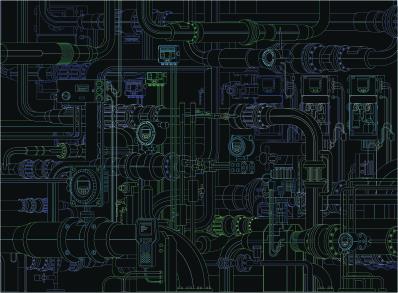

Instrumentation

Needs increased upon industrial revolution and economical income and expense relationship have entailed follow-up and analysis procedures. Process control operations can be seen at all stages of production and monitoring productivity, energy and labor force have become as important as production itself. The significance of instrumentation technology is boosted by time lost by labor force in modern process control systems, control of energy efficiency, variables arising from environmental factors and minimum cost-maximum benefit principles.

Instrumentation is defined as evaluation of measurable physical input in a broad sense. Instrumentation provides the necessary information for process control. Hence, variable structures of cost of production and impacts of those inputs on each other may be examined and standardization of production may be ensured. Correct project design in processes' field instruments and measuring methods allow for making right decisions and producing efficiently at a lower cost.

Field instruments are integrated into PLC/DCS systems through Profibus-DP/PA or HART protocol according to area of application, and DTMs and diagnostic information of field instruments become accessible.

ASTEC performs project design, assembly and commissioning procedures with its technological know-how and process control experience gathered from the projects it completed in the field of field instrumentation in industrial plants.

Process Instruments:

- Pressure Measuring Transmitters

- Level Measuring Transmitters

- Temperature Measuring Transmitters

- Flow Measuring Transmitters

- Analytical Measuring Transmitters (Ph, Conductivity, etc.)

- Dust Measuring Transmitters

- Humidity Measuring Transmitters