Process Tanks and Reactors

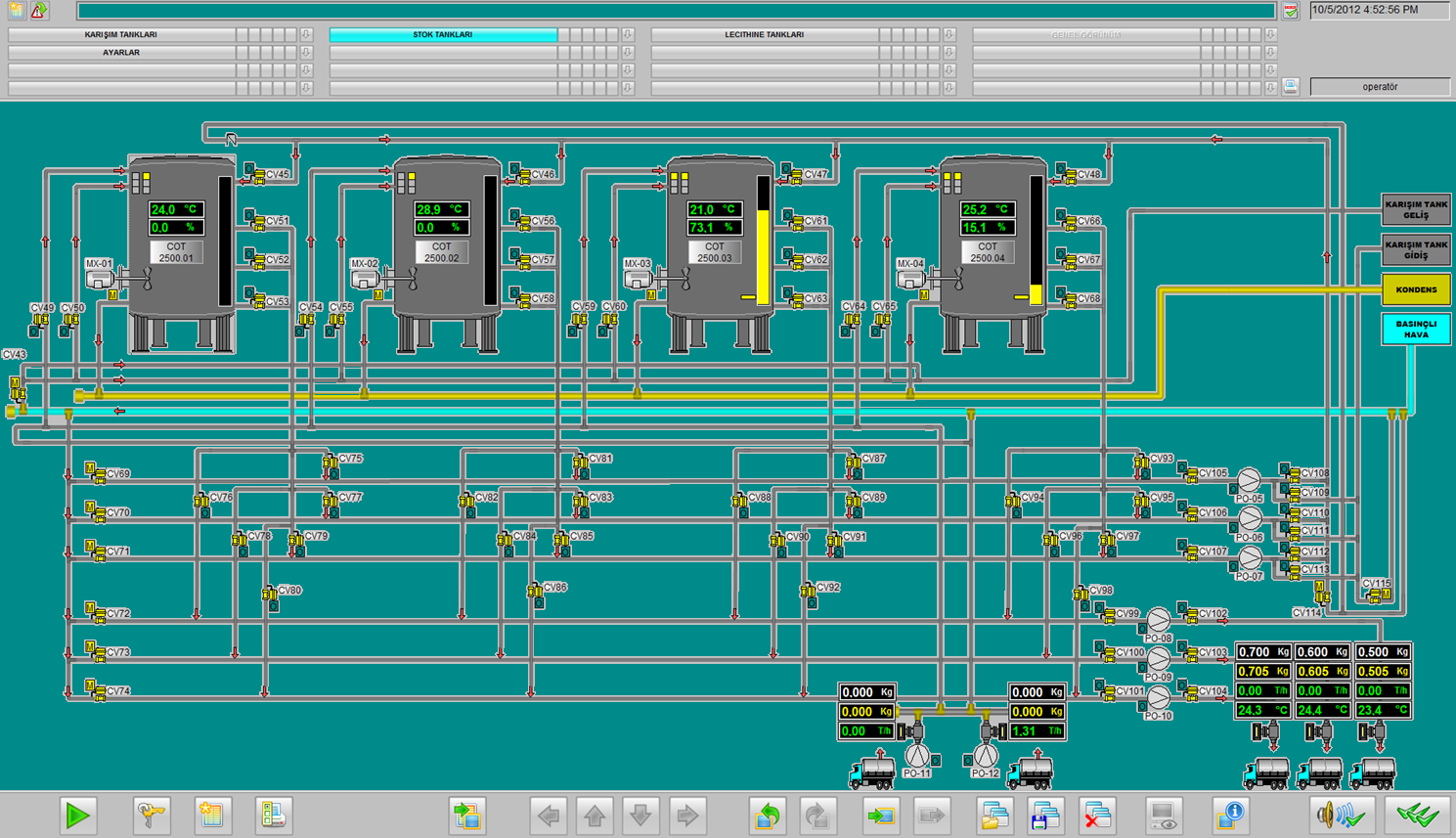

ASTEC Endüstri utilizes a variety of equipment for the purposes of storing liquid and gas in processes, performing reactions and several physical treatments such as distillation, evaporation and absorption.

Reactors are used in processes to accelerate mass and heat transfer rate between two or more different phases. Several physical treatments take place in process reactors including dispersion of a gas in a liquid, emulsification of a liquid in another liquid and dissolution of a solid matter in a liquid.

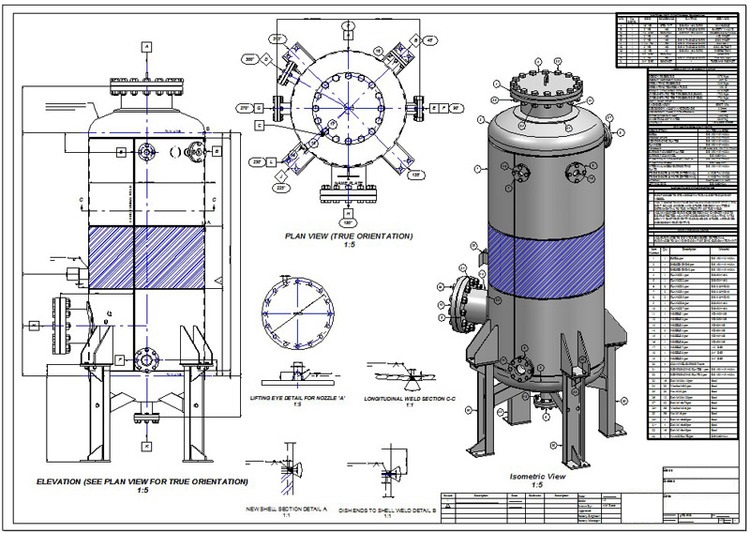

Interior design, which is the first sizing in association with the process to be developed in reactors and tanks allows us to identify main dimensions of equipment. Mechanical design of reactors are carried out by our specialist and experienced chemical and mechanical engineers.

Features of our Reactors and Tanks:

- Vacuumed, high/low pressure, atmospheric,

- Stainless steel, carbon and special alloy products,

- design options as per ASME codes,

- TÜV certified,

- calculation with different endurance options,

- products with mixers, baffles and draft tubes.

Our Process Equipment:

- Mixers and Reactors

- Absorption Columns

- Gas Washing Columns

- Process Tanks (Small and Large Volume)

- Hoppers and Bunkers