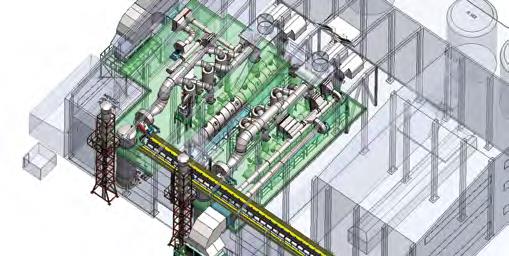

Drying Plants

Drying processes consist of wet product feeding equipment, main drying systems, equipment used in elimination of products to ensure size distribution according to market needs/limitations where final treatment is applied to solid fresh out of dryer before storing, drying to improve storage characteristics, as well as processes applied to gas phase to the products out of drying plant (i.e. minimizing solid leaks and compliance to environmental regulations).

ASTEC Endüstri chooses process design taking into consideration below characteristics of the product to be dried:

- Products chemical properties,

- Structural deteriorations,

- Temperature zone,

- Thermal characteristics (TGA \ DTA \ DSC),

- Product's particle size (m \ cm),

- Product shape (spherical, cubical, bar-shaped),

- Product's internal structure (porous or nonporous).

Those optimal processes which best meet the conditions should be preferred considering the share of drying systems on operational costs. Design of drying processes are carried out by our specialist and experienced chemical and mechanical engineers.

Our Process Equipment:

- Fluid-bed Dryers

- Rotary Dryers

- Spray Dryers

- Flash Dryers

- Band Dryers