Evaporation Plants

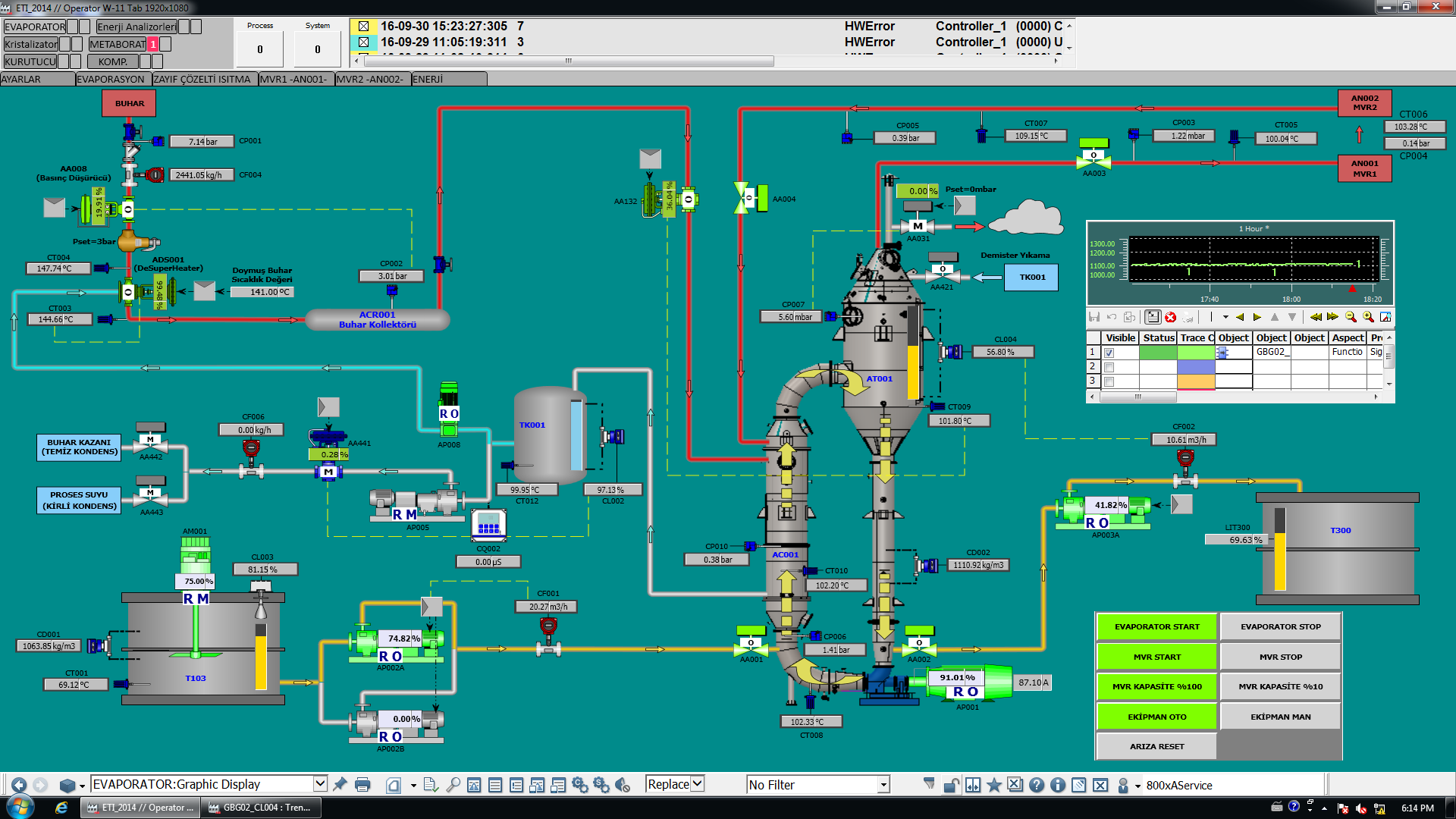

An evaporation process is concentration of a process solution by vaporization under specified pressure of solvent in the solution by heating up until its boiling point is reached. Evaporation process is completed upon obtaining adequate energy to separate water molecules in the form of vapor from solid solution or unvaporizable liquid.

Evaporation process takes place under vacuum, atmospheric pressure and positive pressure while it is ensured the best process method is identified for the plant taking into account product properties such as viscosity, boiling point, etc.

Liquid to be evaporated is heated up until its boiling point in accordance with process evaporation type chosen via heat exchanger and evaporation occurs at the vaporization surface over the separator.

ASTEC Endüstri can produce both single-stage and multiple-stage evaporator designs. Multiple-impact evaporators have positive impacts on energy economy due to the facts that it allows exhaust steam to be used as a heating device in subsequent impacts and provides heat recovery.

Considering the share of evaporation systems on the cost of final product, those processes, in which particularly MVR (Mechanical Vapor Recompression) technology is used standalone or TVR (Thermal Vapor Recompression) technologies are used in combination with each other, should be chosen.

Our Process Equipment:

- Force-Circulation Type Evaporator

- Falling - Film Type Evaporator

- Rising - Film Type Evaporator

- Multi-Stage Type Evaporator

- TVR / MVR Recompression Type Evaporator