Heat Exchangers and Condensers

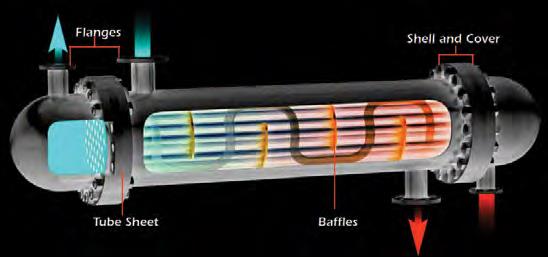

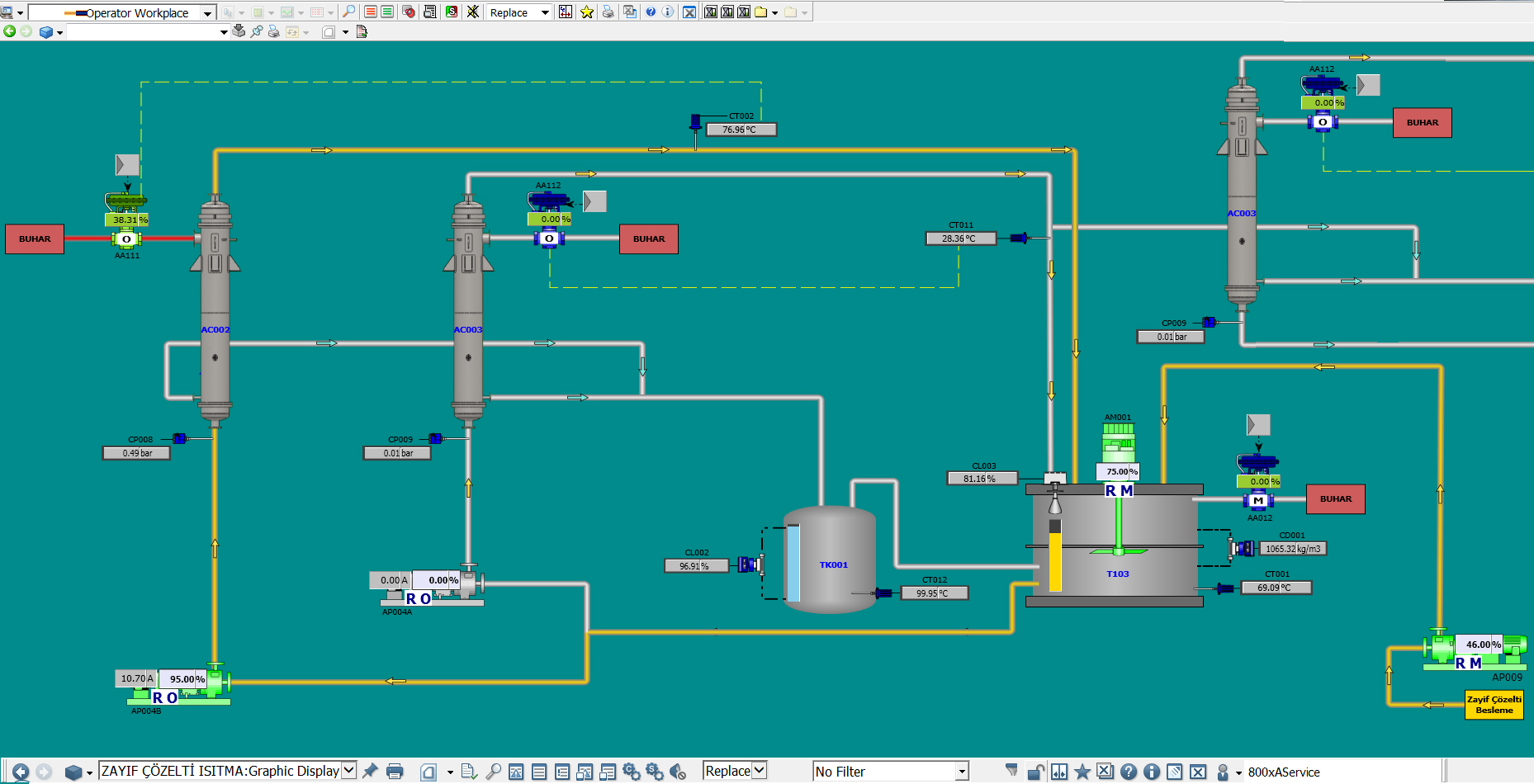

Heat exchangers facilitate heat exchange between two fluids of different temperatures in industrial processes. Reactions and physical treatments used in chemical processes always require energy exchange at different levels. This energy exchange must be ensured by cooling or heating up for working on a steady state in chemical production processes. Therefore, use of heat exchangers are essential in chemical processes.

At ASTEC Endüstri, design and sizing of heat exchangers and condensers with computer-assisted programs based on the process and their area of application, and drawing up of equipment's basic/detailed projects are carried out by our knowledgeable and experienced chemical and mechanical engineers.

We use two types of heat exchangers in our processes: direct-contact heat exchangers and indirect-contact heat exchangers.

Design/production steps of Heat Exchangers and Condensers:

- Classification of heat exchangers and identification of key design parameters,

- Thermal design of heat exchangers in accordance with existing relevant standards (PED 97/23/EC) (Defining required piping layout, number and length of the pipes, etc.)

- Mechanical design of heat exchangers upon completion of thermal design

Our Process Equipment:

- Tubular Exchangers

- Plate Exchangers

- On/Off Type Condensers