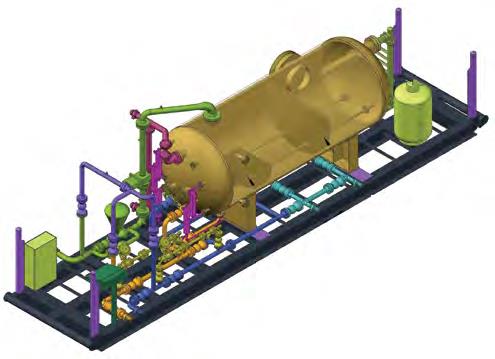

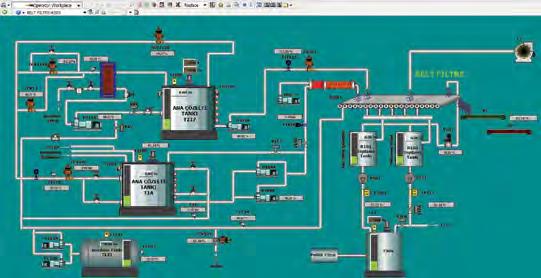

Separation and Filtration Plants

Liquid-solid separation is used in industrial processes for a wide range of different purposes. The most significant factors in identifying the process method to be applied are whether liquid or solid is more valuable, separation efficiency and affordability of the method to be adopted and investment cost.

ASTEC Endüstri identifies technologies that best fit to the needs of plants with regards to Separation and Filtration.

- We utilize polish filtration method for refining liquid phase, which is headed to the equipment in which final product composition will be obtained (Crystallizer, Evaporator, etc.), from solid that it contains and that does not dissolve in liquid phase, and for ensuring product's purity. To that end, we generally use pressure filters of any type.

- The purpose of processes in which solid is enriched by simple methods in solid-liquid mixtures is not to make a precise solid-liquid separation, but to ease the workload for devices that will perform subsequent solid-liquid separations. Within this scope, thickeners and hydrocyclones are used in this kind of processes.

- Filters and centrifuges, the process equipment in which solid-liquid separation takes place at the ultimate levels, are designed according to process properties and installed to plants we build.

Our Process Equipment:

- Vacuum Belt Filter

- Polish Filter

- Pusher Centrifuge Filter